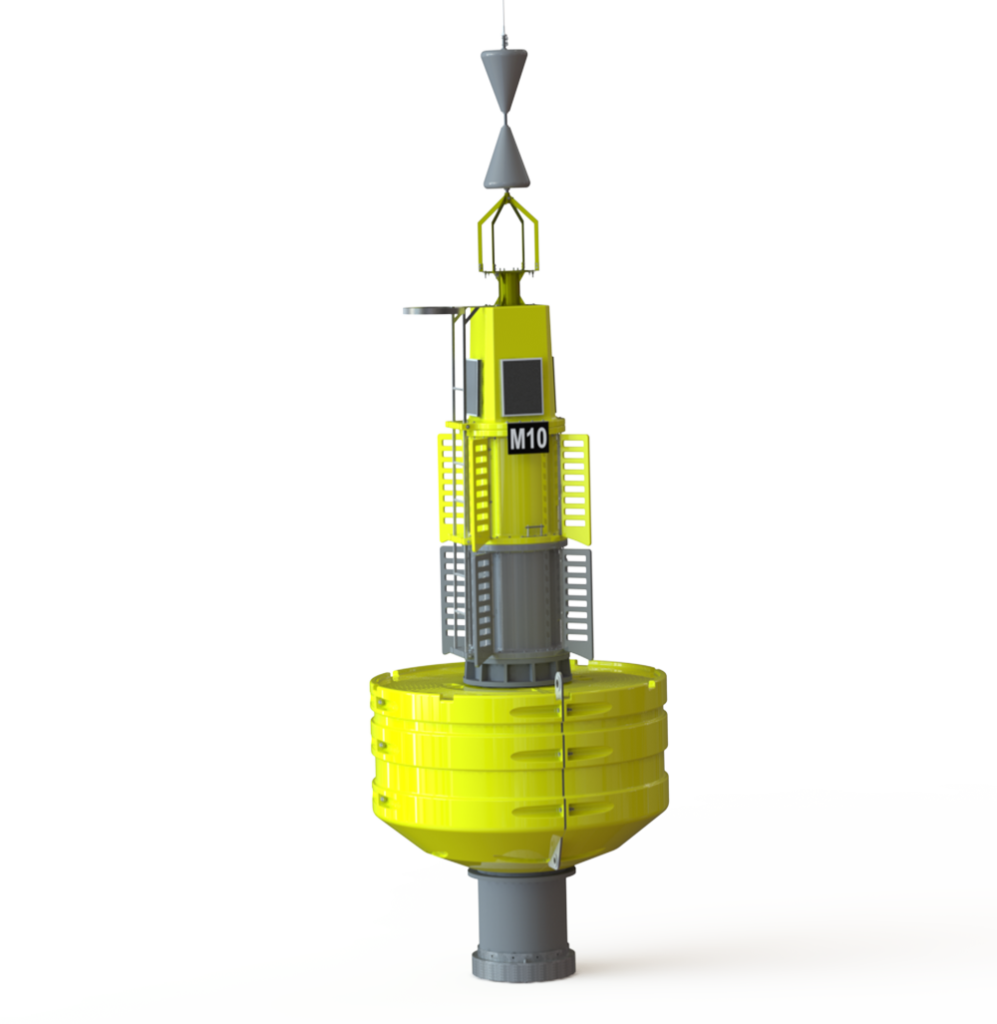

SB-3.0 Buoy

Sentinel® Buoy

The SB-3.0 has a fully modular design which is configurable to meet most of the demands of our customers. Manufactured using the latest raw materials and construction methods, the buoy is fully compliant with IALA Guidelines. Medium Density Polyethylene float sections form the heart of the buoy giving it physical strength that resists damage. The buoys unique design and controlled manufacturing process ensure a homogeneous profile with an increased thickness in high stress areas.

Characteristics

- Central Core manufactured from either High Density Polyethylene (HDPE) or Galvanized Steel. The design allows each of the hull sections to be easily fitted and quickly replaced if damaged. As an option the Central Core can be fitted with zinc anodes.

- The buoy has two lifting and two mooring eyes; they are manufactured from 316 Stainless Steel for the HDPE Core option and Galvanised Steel for the Galvanised Steel Core option.

- The tower can be manufactured from MDPE in either a two module or three module configuration or Galvanized Steel painted in line with IALA requirements. The steel tower can only be fitted on the steel Central Core.

- When required, the top section of the tower can be fitted with additional solar panels and an optional battery box and lockable hatch can be fitted in the base of the tower.

- All IALA configurations are available.

- The buoy is available with the following options:-

- Stainless Steel Ladder rated for over 200kgs

- Nameplates

- Aluminium or Polyethylene Top Mark

- Polyethylene Day Mark Panels to improve daytime visibility

Benefits

- Central Core design allows each of the hull sections to be easily fitted and quickly replaced if damaged.

- Outstanding colour retention and physical strength that resists damage.

- Medium Density Polyethylene repels marine growth.